Beverage production

Mastering future code requirements

Beverage production

Mastering future code requirements

Newly introduced CO₂ laser coders are designed to help beverage manufacturers prepare for future high-resolution coding requirements now. Domino Printing Sciences is demonstrating 30 per cent faster coding than the previous generation of CO₂ coders.

"The global laser market is expected to grow at an annual rate of 10 per cent between 2023 and 2029," says Felix Rief, Head of Laser and Extraction at Domino. This growth can be at least partly attributed to the increasing demand for high-resolution 2D codes on packaging, including QR codes from GS1. "This is being driven by the GS1 Sunrise initiative, which provides for the acceptance of 2D codes in the retail sector. These new code requirements increase the need for reliable, high-resolution on-product printing solutions that do not compromise production speed," says Rief. The company has introduced the new Dx series CO₂ laser coders for variable data printing. A well-known North American bottling plant was one of the first to test the product. "The customer's lines are very fast with speeds in excess of 70,000 bottles per hour, and the environmental conditions present an additional challenge as high humidity and moisture cause condensation on the product," explains Jon Hall, Senior Product Marketing Manager - Laser, Domino North America. Speed, code clarity and product reliability were the main focus. "The trial was extremely successful with over 30 million codes successfully delivered and a very satisfied customer," summarises Hall.

Secure printing at high speed

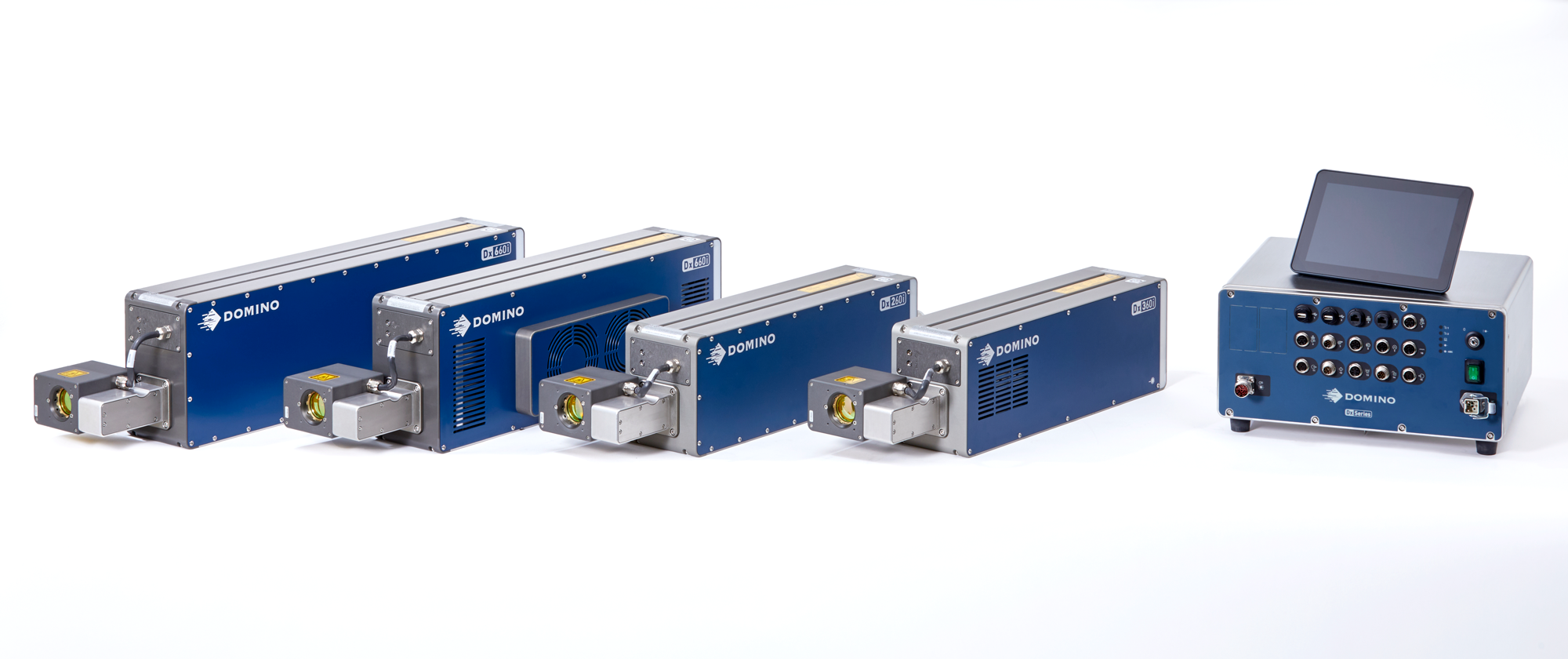

₂In the beverage sector, it is common for bottling plants to require coding and labelling systems that can mark 70,000 to 90,000 bottles per hour, depending on the material. Reliably printing 2D codes at such high speeds can be a huge challenge, and in the past, manufacturers have had to slow down production lines to achieve the required quality. The Dx Series CO₂ lasers have been developed to help beverage manufacturers meet the increasing code requirements. A new coding algorithm enables up to 30 per cent faster coding to achieve the required speeds - with low substrate load and without compromising code quality. The Dx series lasers are robust and resistant and are suitable for the challenging temperatures, humidity and condensation often found in bottling plants. The CO₂ lasers are designed to operate in temperatures of up to 45 °C and feature an IP55-certified controller and an optional IP65-certified printhead variant (standard IP54-certified) for additional protection against the ingress of dust and water. The entire range of laser marking systems is available with a new range of laser extractors to remove dust and vapours to ensure marking quality and increase the life of the laser equipment. The Dx Series lasers have been designed with flexible beam guidance and customisation options so they can be mounted in any orientation to apply variable data to the neck, side or base of beverage bottles during production. The Dx series includes the Dx260i (20 watt), Dx360i (30 watt) and Dx660i (60 watt) models and offers options for different materials and code requirements. The 20 and 30 watt solutions are suitable for printing labels, pouches and bottle corks, while the more powerful 60 watt solution is suitable for high speed coding on PET and glass as well as large format, complex code requirements, for example replicating the contents of entire labels to support the move to label-free bottles.

Pictures: Domino

The Dx series comprises the models Dx260i (20 watts), Dx360i (30 watts) and Dx660i (60 watts).