image: Nord Drivesystems

Nord offers customised, economical and sustainable drive solutions from its modular product system for all stages of the packaging process - including decentralised solutions for end-of-line packaging.

Packaging optimisation

Efficient logistics and transport packaging

The processes in industrial packaging are highly automated in order to make the individual steps as efficient as possible. However, centralised drive systems are increasingly reaching their limits, particularly in the area of tertiary packaging, i.e. end-of-line packaging. The solution can be a decentralised approach that allows users to increase their system efficiency and save significant costs at the same time. The innovative drive systems and expertise of Nord Drivesystems can help here.

When it comes to packaging goods and products at the end of the industrial production process, efficiency and flexibility are increasingly in focus for various reasons: high cost pressure, maximum cost-effectiveness with greater sustainability and environmental protection are just some of the factors in this area of conflict. Products are becoming increasingly complex and require special handling, and packaging itself is also more complex, for example due to new formats or frequently changing batch sizes. The demands placed on modern drive technology are correspondingly high. This applies to all three areas of packaging, primary, secondary and tertiary packaging. The choice of the most suitable system architecture in each case can hardly be underestimated and gives companies a decisive competitive advantage. Primary packaging systems are usually very compact and, depending on the industry, also consist of washdown-capable components. They must be fast, precise and capable of highly dynamic movements in order to guarantee high production rates. Typical machines in the secondary packaging sector include cartoners, shrink wrappers, shrink sleeve and film packers. A very high degree of flexibility is required here in order to process different types and sizes of packaging.

Tertiary packaging with high dynamics and precision

In tertiary packaging, or end-of-line packaging, the bundled products from the secondary packaging are palletised and stabilised for further transport or storage. "In this area, drive technology must be able to safely handle or move the sometimes very heavy loads at high speed and with equally high precision," says Stefan Blust, Industry Sector Manager Packaging at Nord Drivesystems, who has extensive expertise in automation technology.

"Dynamics and precision are essential in all three of these areas. In end-of-line packaging, we achieve ramp times of between one second and 0.5 seconds; the movements can be very dynamic, especially with gantry and storage palletisers. For linear movements, we are talking about a positioning accuracy of around one millimetre and angular movements of around 30 angular minutes, converted to 0.5 degrees." These dynamic values are exemplary and can vary depending on the machine type."

Centrally controlled systems with high costs

Centrally controlled servomotors are still widely used in tertiary packaging systems. The biggest problem facing a company with a complex packaging system will be the high costs that the system incurs over time. Not only is the purchase of the technology expensive - the installation and maintenance costs are also a major factor with servo motors. If such a system is to be expanded, for example to increase capacity, the high space requirement becomes a further disadvantage: not only is there limited space in the control cabinet, but the centrally controlled servomotors plus controller, which have to be installed with each additional machine, also take up space. In addition, there are new cable ducts and a lot of time and costs for the cabling. "People often forget that with the new system components in the control cabinet, the necessary cooling also becomes a factor that reduces energy efficiency," explains Stefan Blust. "Then there are the challenges with regard to electromagnetic compatibility, when more and more load and control cables, for example from the sensors, inevitably cross in the control cabinet."

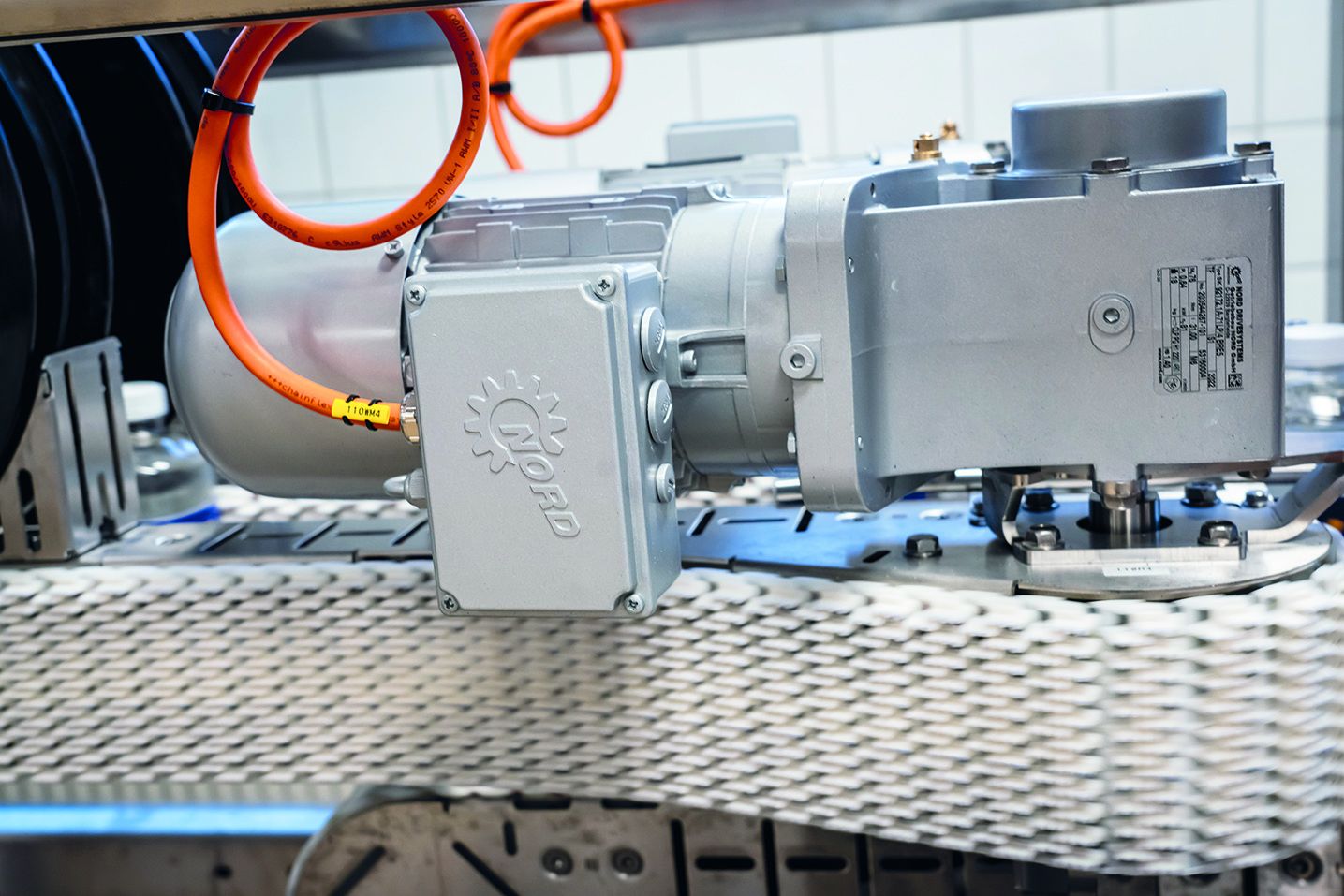

Example of a decentrally controlled Nord drive unit - combination of IE3 asynchronous motor with a Nordbloc.1 bevel gearbox and a Nordac ON frequency inverter, here installed in a plastic chain conveyor.

However, if the entire system is and remains rather small and the distance between the control cabinet and drive technology is also small, a centralised system like this can certainly work with good efficiency. However, when it comes to more complex applications with several large machines and further distances to be bridged, the centralised approach reaches a point at which operation or expansion is no longer economical.

Decentralised drive technology - an alternative with a future

The situation is different with a decentralised system: "Here, the frequency inverters are located directly on the motors and the PLC can be placed in a much smaller control cabinet. The cabling effort is reduced accordingly, as only one power and one data line lead to each motor," says the automation expert, explaining the principle. "This can also be askadable, and because only two cables come out of the control cabinet, this results in a very space-saving and efficient solution - especially for systems with a wide spatial extension and a large number of drive axes, as is the case with end-of-line packaging." An example from the mechanical engineering sector shows just how high the savings potential can be: by switching from servo technology to decentrally controlled drive technology in its palletising machines, a company was able to reduce its total operating costs by almost 50 percent. At the same time, the performance of the system increased. In detail, a typical example of a decentrally controlled drive unit consists of a gearbox, an asynchronous motor, an encoder feedback and a frequency inverter with PLC functionality and positioning software (Posicon) mounted directly on the motor, which maps a control loop in the system. In addition to the position, torques and speed can also be controlled. The integrated PLC also relieves the main PLC and ensures quick and easy commissioning. The individual components are selected so that they fulfil the respective requirements. The experts help with their know-how and determine in a technical discussion with the customer which options are available to increase system efficiency with a decentralised system. Thanks to Nord's portfolio, users have a wealth of choice and can select the optimum solution for them from the modular product system - the keyword here is modularity.

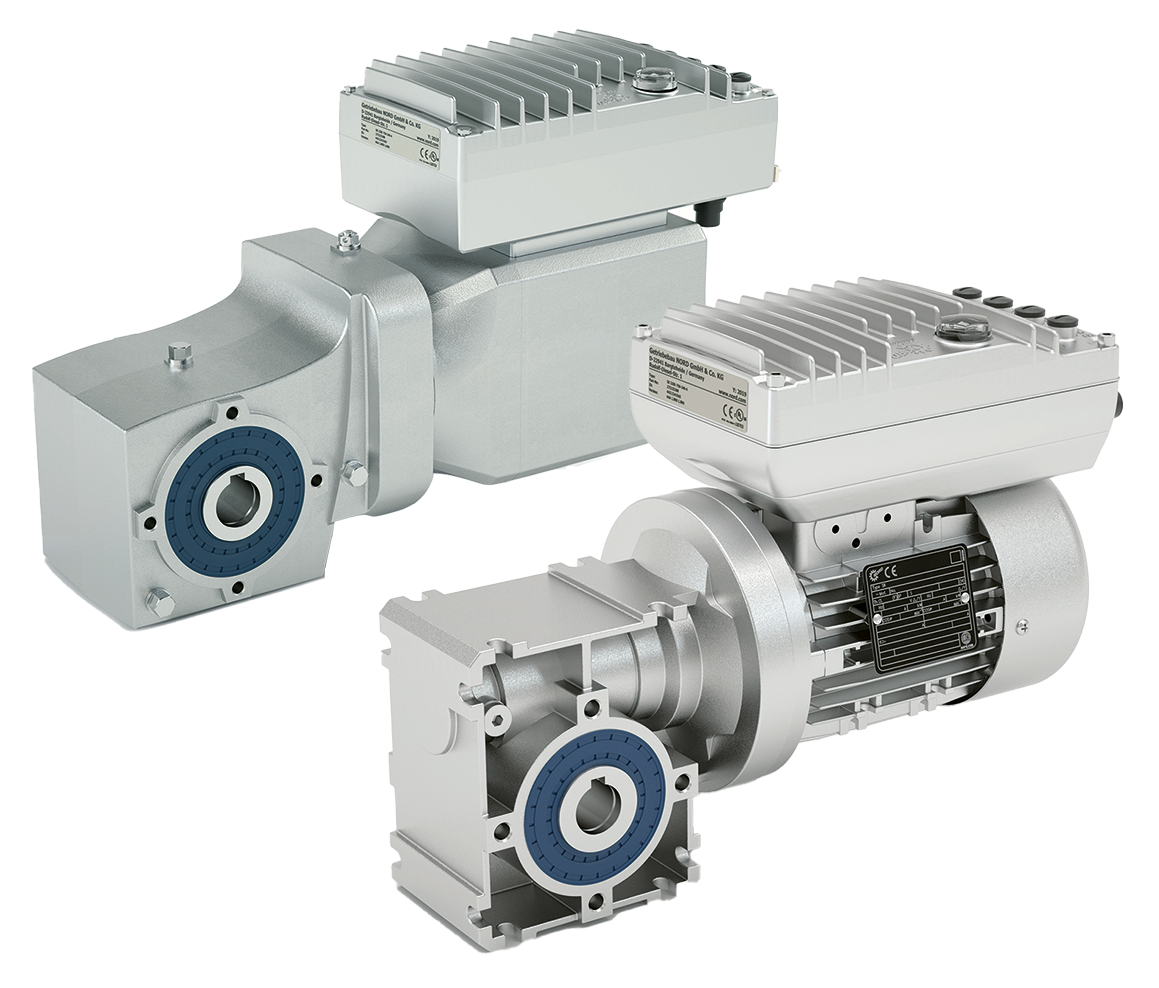

The Nordac ON frequency inverters with plug-and-play functionality cover a power range from 0.37 kW to 3.7 kW.

Modular product kit, readily available standard components

Proven combinations consist, for example, of Nord IE3 asynchronous motors with a Nordbloc.1 bevel gearbox and a mounted Nordac ON frequency inverter. The main features of the Nordac ON family are its compact design, full plug-in capability, plug-and-play functionality and high reliability. They cover a power range from 0.37 kW to 3.7 kW. The pluggability is important for efficient, cost-saving operation in that it minimises maintenance requirements: Defective components can be replaced quickly and easily in this way, minimising downtime. "The high overload capacity of our components should also be mentioned," adds Stefan Blust. "In some cases, the loads in end-of-line packaging can be very high. In practice, we see that our components can easily withstand this with an overload capacity of up to 200 per cent. The control electronics, which are tailored to this package with their dynamic stability, also contribute to the high performance of our decentralised drive solutions." Practical applications for the decentralised drive solutions include gantry palletisers with grippers, linear palletisers and, in the field of pallet stabilisation, stretch hood wrappers, arm and ring wrappers, which wrap the products packed on the pallet with a film. For ring wrappers, drives with flat gears are used for vertical film tension, while other applications can be realised with bevel, spur and worm gears. Strapping machines are also among the possible applications for decentralised drive technology. They use belts - mounted vertically or horizontally - to stabilise the usually heavy goods.

Decentralised saves time and costs

For companies in the packaging industry, decentralised drive solutions offer great potential for reducing operating costs, especially in tertiary packaging. Other tangible benefits include energy-efficient motors, quick and easy installation, reduced component space requirements and high flexibility and scalability. The choice of decentralised drive technology can become a decisive competitive advantage.