Sealing the Future

New design instead of further development

Stefan Dangel, Head of Sales and Marketing at Oldenburg-based machine manufacturer and packaging specialist Sealpac, told us why Sealpac has set up its own thermoforming division and why screwing cold sealing plates into hot upper moulds is not always advisable when changing formats.

Images: Sealpac

Mr Dangel, how do you assess the current market situation? What challenges and opportunities does it present?

Stefan Dangel: The fresh meat segment, one of our core markets, is undergoing a partial reorganisation, but this is precisely what opens up new opportunities. While the red meat segment has weakened recently, a kind of bottoming out and the first signs of recovery have been evident for some time. At the same time, we are experiencing strong growth in the white meat and convenience segments. These developments are also having a significant impact on our sector. In general, after a phase of defensive market orientation, we are once again seeing a significant increase in activity in almost all areas. In the wake of the general market turbulence, suppliers of packaging machines and solutions are also noticing that companies are making more targeted investments and acting more innovatively. Food producers are increasingly focussing on sustainable and technologically advanced solutions in order to adapt to current market requirements. Digitalisation and automation are playing an increasingly important role in this, as they enable more efficient production and optimised processes. In short: flexible and easy-to-integrate cutting-edge technology is being sought, and the disadvantages of so-called "one-stop-shop solutions" are being increasingly recognised.

What strategy has Sealpac adopted in the generally challenging market phases?

Dangel: We have positioned ourselves as a specialist for traysealers and thermoformers, including the appropriate packaging solutions, without pursuing a large number of additional solutions in the upstream and downstream areas. This focus has enabled us to deploy our resources in a targeted manner, concentrate technologically on our core business and thus establish ourselves as one of the leading suppliers of traysealers and thermoformers. This strategy has proven to be particularly advantageous in economically uncertain times, such as during the coronavirus pandemic or in phases of geopolitical uncertainty: We were able to expand our strengths in a targeted manner and maintain a stable position on the market.

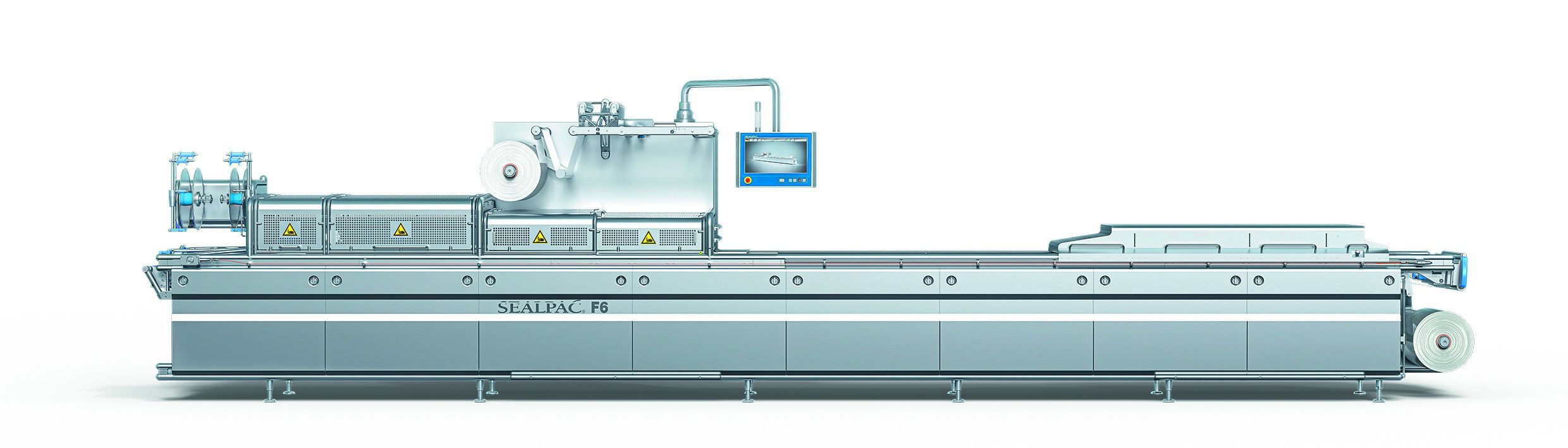

At Iffa, you presented the F-Series thermoforming machine range as a world premiere. To what extent do these machines set new standards?

Dangel: As an example, we have exhibited the F6 model, one of currently three model variants. Our F-series thermoformers are the result of a completely new design idea. We deliberately decided against an evolutionary further development of existing solutions and instead ventured a completely new concept. This has enabled us to eliminate the old obstacles and develop a thermoforming system that fulfils the latest requirements. With more than two decades of experience in the thermoforming segment, we were able to critically scrutinise the so-called "standards" that are customary in the industry. One example: screwing cold sealing plates into hot upper moulds when changing formats is common practice in the industry, but is not recommended for the process under the principles of material science. In this case, we have decided in favour of a complete change of the upper sealing tool instead. Although this initially means a higher, calculable initial investment, it is a far more economical solution in the long term from a holistic perspective, as the cost structures for maintenance and servicing remain within a very predictable framework. The innovative mould changing system ensures a significant reduction in downtimes and therefore increases the availability of the systems. Flexibility was also at the centre of our development work: users can change over to different packaging formats and materials with little effort and virtually no auxiliary tools. Our motto is plug&pack instead of set&adjust.

Our motto is plug&pack instead of set&adjust. That's why flexibility was at the centre of our development work for the F series.

Stefan Dangel Sales and Marketing Manager marketing manager Sealpac

What else could you improve in the machine series?

Dangel: A key feature of the new F series is the energy-efficient control of the heating and cooling systems. Optimised process sequences have enabled us to significantly reduce energy consumption. The control technology also enables precise process monitoring. This reduces machine downtimes and allows maintenance work to be planned in advance. The user-friendliness of the system was also particularly important to us. With an intuitive user interface and extended automation functions, we make it easier for users to operate the machine and reduce the amount of training required for staff.

The introduction of the F-Series also marks a transition from your previous partnership in the thermoforming sector, which will come to an end in the future. How will the business activities in the thermoforming sector be continued?

Dangel: Our cooperation in the thermoforming sector has existed since 2004. Due to the recent takeover of this company, we have jointly agreed in constructive and cooperative talks that our partnership in the area of new machines will expire at the end of 2026 - with appropriate precautions, of course. The talks took place in a good, solution-orientated atmosphere. Everyone involved is aware of their responsibility to the market. That is why we have jointly developed a long-term strategy to ensure the long-term supply of spare parts and service. This is why we have launched our own thermoforming division with the new F series and at the same time set up a second plant in Oldenburg. This means that in future our traysealers and thermoforming systems will be manufactured 100 per cent in Germany. The second plant, also in Oldenburg, is also the result of strategic risk protection against external influences such as natural disasters and/or supply bottlenecks. We have also further expanded our service network.

How do companies manage to keep creating new innovations and quality standards?

Dangel: As an owner-managed, medium-sized company with almost 40 years of experience, we focussed on innovation and a sustainable cost structure at an early stage. Our core expertise lies in primary packaging technology: we focus exclusively on the production and further development of traysealers and thermoformers, but not additional solutions in the upstream and downstream area, as mentioned at the beginning. Our systems are designed to work seamlessly with all standard upstream and downstream solutions on the market. We continuously monitor the market so that we can carefully evaluate new developments and respond with innovative and marketable solutions. Our research and development department works closely with users to develop customised solutions. Overall, focussing on the core areas of primary packaging technology, ongoing curiosity, precise market analysis and a well-founded assessment of developments are a reliable indicator of future success.

What are Sealpac's strategic goals for the next five years and how do you want the company to develop?

Dangel: Sealpac will continue to remain independent and flexible in the dynamic fresh food market. We are focussing on short decision-making processes and the further development of our technologies. In addition, the next family generation is already ready to gradually take over responsibility in the coming years. Our strategy for the next five years includes expanding our existing partnerships in order to broaden our presence on the markets. At the same time, we are focusing on sustainable production and optimised use of resources in order to further reduce the ecological footprint of our machines. We are also focusing on the digitalisation of our production processes and the further development of Industry 4.0 applications. (mns)