Quality Management

Snacks and confectionery Fast and safe packaging

In the snack and confectionery industry, where speed and quality go together like salt and pepper, manufacturers face the constant challenge of meeting consumer demands while maintaining product integrity.

Snacks are becoming increasingly popular worldwide. In fact, global sales of savoury snacks are predicted to reach $386.8 billion by 2030. It is therefore clear that the pressure to deliver a diverse range of high-quality products quickly is greater than ever before.

Challenges in high-speed production

The high-speed production of snacks and confectionery presents several challenges, particularly when it comes to product handling and rejection. When products are processed at high speeds, they are more susceptible to damage or misalignment. This in turn leads to higher rejection rates. The handling of delicate items or products with specific packaging requirements, such as tubular bags, becomes more complex as speed increases, increasing the risk of product rejection and waste.

Weighing challenges

The sealed edges of tubular bags, which can cause handling and sorting issues, as well as the need for tighter tolerances on smaller products, make it even more difficult to perform accurate weighing operations. Advanced dynamic checkweighers with FlashCell technology from Mettler-Toledo help solve this problem by handling products effectively and enabling short weighing times. In addition to reliable handling, they also offer greater accuracy. Even at speeds of up to 800 products per minute, the systems deliver consistent weighing results and consistently high quality.

Foreign body detection

Maintaining product purity - critical for snacks and confectionery - can be a real challenge due to the high speeds and variety of products on the production line. Effective contaminant detection is therefore essential for both unwrapped and wrapped products. Manufacturers can use a combination of metal detection and x-ray inspection technology to fulfil these requirements efficiently.

Metal detection and x-ray inspection

Metal detection systems specialise in the detection of metallic contaminants such as ferrous, non-ferrous and stainless steel particles. They generate an electromagnetic field and identify metal particles that interfere with this field. Metal detection systems can be used at various points in the production line, whether for inspecting raw materials before the start of production or at the end of the production line after primary packaging. However, the most frequently chosen installation location in the production of snacks and confectionery is immediately before packaging. The products are weighed using multi-head weighing technology, fall through the metal detector and enter the bag, which is then sealed. The technology is ideal for high-speed production environments where fast and accurate detection of metallic contaminants is required. Inspection at this point minimises the risk of metallic contaminants in the final product and avoids any inspection limitations of the packaging material during primary or secondary packaging. Technologies such as Mettler-Toledo's Automated Test System (ATS), which not only improves test accuracy and shortens test time, but also reduces the number of operators required to perform the tests from two to one, can further increase productivity. In terms of total cost of ownership, metal detection technology is the best choice at this critical control point (CCP). Metal detection systems deliver efficient and accurate results in both horizontal and vertical applications. Vertical inspection systems, particularly utilising free-fall metal detectors in vertical form fill seal (VFFS) applications, are proving to be highly effective in the inspection of products such as snacks and crisps. These metal detection systems are installed between the weigher and the bag machine, allowing free-falling products to be inspected as they travel through the system. This method detects foreign objects before packaging, which is particularly beneficial in high-speed production environments. X-ray inspection systems are ideal for detecting a wide range of foreign bodies in packaged products, both in primary and secondary packaging. X-ray inspection enables the detection of glass, metal, stones, dense plastics, rubber compounds and even agglomerates - a problem often faced by chip manufacturers. Agglomerates or clumped seasoning powder can form during the manufacturing process and affect product quality by altering flavour, texture and appearance. The X-rays penetrate the packaging and identify foreign bodies contained therein based on differences in density. While inline inspection is effective for individual tubular bags, for example, end-of-line inspection, such as scanning an entire box of chocolate bars, offers additional benefits. This means that each box is thoroughly inspected for foreign bodies before it reaches the retailer. This multi-stage inspection process significantly improves product safety and quality control. In addition to foreign body detection, x-ray inspection systems perform a range of integrity checks such as verifying product shape, determining mass, detecting missing or broken products and checking for correct fill level. This further improves quality control and minimises the risk of defective products reaching consumers. The selection of the most suitable technology for a production line depends on the product type and the risk of contamination. Metal detection systems are ideal for inspecting products before packaging or during primary packaging. Early detection of metal contaminants at this stage saves manufacturers production costs. X-ray inspection systems are favoured for packaged products where detection of a wider range of contaminants is required. They are suitable for packaged products and offer optional quality and integrity checks that can take place simultaneously, usually at the end of the line.

Cost pressure

A major issue for manufacturers in this industry is cost pressure. In particular, the fact that many snack and confectionery products are sold at low prices makes it difficult to invest in high-end product inspection systems. While the upfront cost of metal detection or x-ray inspection systems may seem high, these technologies can significantly reduce the cost of recalls and potential reputational damage. Utilising AI-driven functions with a focus on sustainability offers manufacturers additional support. By optimising inspection efficiency with intelligent algorithms, manufacturers can reduce energy consumption and minimise waste, ultimately reducing operating costs.

Foreign bodies made of plastic

Particularly in confectionery and snack production, where complex machinery and moulds are often used, there is a risk of plastic contaminants entering products alongside metal contaminants. Plastic foreign bodies can result from wear on moulds, broken machine parts or damaged packaging materials. Robust detection systems are therefore essential. X-ray inspection systems offer an effective solution for detecting plastic contaminants based on their density, even when the difference in density between the plastic and the product itself is minimal. Despite the challenges, x-ray inspection systems can be accurately calibrated to detect different types of plastics, from dense polypropylene fragments to lighter plastic films, in applications with a wide range of product types. Confectionery products, whose ingredients can vary greatly in texture and density, can pose problems for traditional inspection methods when it comes to detecting plastic contaminants. However, x-ray inspection technologies offer greater detection sensitivity and reliability, ensuring products always meet stringent safety and quality standards. This minimises the risk of plastic contaminants reaching consumers and protects brand reputation.

Robust testing and set-up procedures

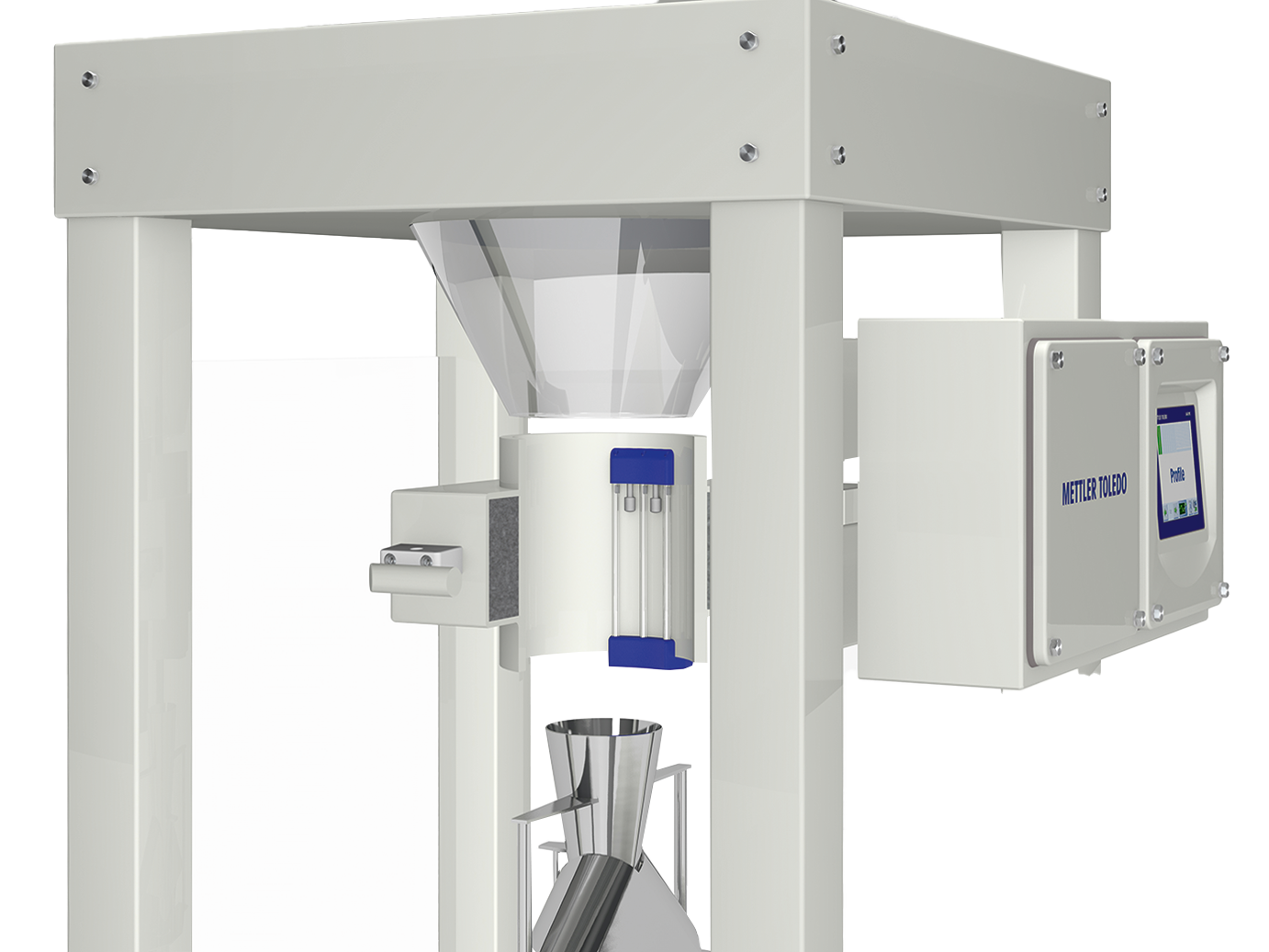

optimised for foreign body detection, manufacturers can integrate automated test systems. Mettler-Toledo's Automated Test System (ATS), for example, automates the testing process for metal detectors integrated into vertical moulding, filling and sealing processes. The ATS provides precise verification of detection sensitivity at the centre of the aperture, where contaminants are most difficult to detect, by simulating the position of contaminants. With consistent performance testing and a reduced risk of undetected contaminants, this method increases manufacturers' confidence in product safety. X-ray inspection systems enable the automatic set-up of inspection functions for different products and simplify item changeovers to optimise processes and reduce the risk of human error. By automatically adapting to new products or packaging formats, x-ray inspection systems ensure consistently high inspection accuracy as the correct detection sensitivity is always set for the product in question.

The automated test system optimises the testing process for vertical form, fill and seal processes.

Images: Mettler-Toledo

System cleaning and hygienic design

Another typical challenge is the accumulation of sugar and flour dust, which can lead to corrosion and contamination in production facilities. At critical control points in the early stages of production, it is important to select metal detection systems that minimise the loss of good product during the rejection process. It is advisable to consider dust-tight seals as part of the system specification. Downstream, where goods are inspected on a conveyor belt, the solution is to install IP65 and IP69 rated inspection systems that are designed for easy cleaning and can withstand intensive cleaning procedures.

Verification of labelling and allergen information

Increasingly stringent regulations, such as the Natasha Act passed in the UK, have made the verification of labelling and allergen claims critical aspects of food safety. The Natasha Act stipulates that all pre-packaged foods intended for direct sale must have a full list of ingredients with clear allergen labelling. This regulation aims to protect all consumers with food allergies and give them access to important information about the products they consume. Automated visual inspection systems play a crucial role in fulfilling these requirements by verifying the information on the labels. They help to maintain compliance, avoid costly recalls and protect the health of consumers. The systems capture high-resolution images of individual product packs as they pass through the production line. They use advanced algorithms to analyse the images and check whether the labels are marked with the correct information, such as lists of ingredients and allergen information. They also recognise printing errors, missing information or incorrect labels.

Data management in production

Another integral part of modern snack and confectionery production is data management, which enables manufacturers to monitor and optimise their production processes and comply with auditing requirements. optimisation of their production processes and compliance with audit requirements. Added to this are predictive maintenance and real-time analyses, which can help to increase produc tivity. These data management systems enable manufacturers to proactively address production issues, reduce downtime and improve product safety. With Mettler-Toledo's ProdX data management software, manufacturers benefit from real-time data collection and analysis for improved compliance and quality assurance. The data management software efficiently tracks and documents product inspection data, providing the essential foundation for meeting product safety standards and optimising operational efficiency.

Investment in inspection technologies is essential

As the snacks and confectionery market continues to boom, manufacturers need systems that are adaptable to new product lines and regulatory changes. Investing in advanced product inspection technologies is essential to maintain quality at high production speeds while future-proofing production lines. With the innovative solutions available, manufacturers can overcome these challenges while maintaining product integrity and consumer safety.

Author: Rob Stevens, Market Manager at Mettler-Toledo Product Inspection