A closer look at multi-web labels

Communication talent in a small space

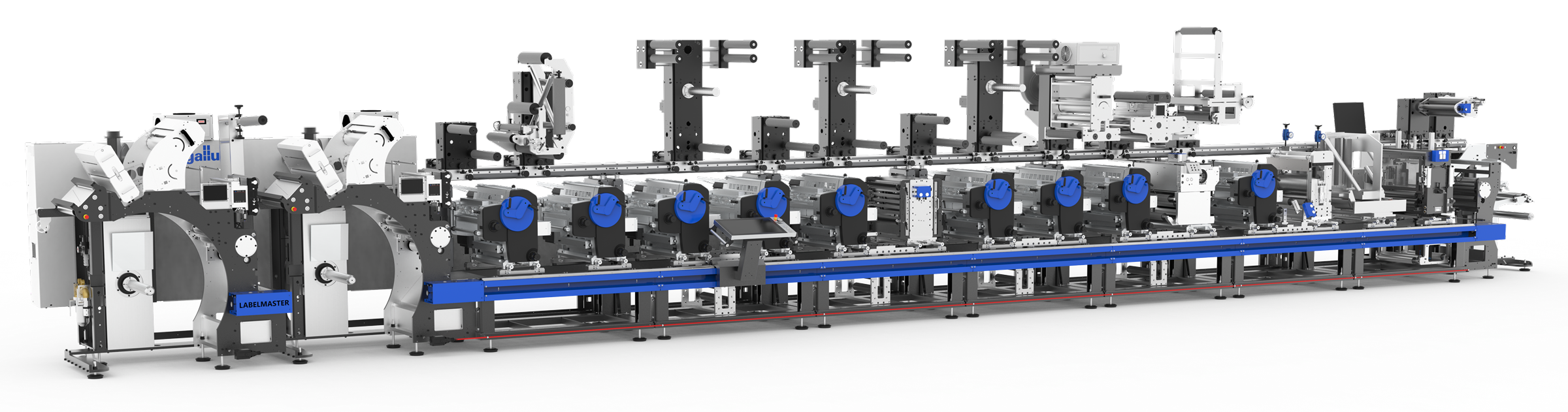

Multi-layer labels are true communication talents. Their multi-layer structure offers plenty of space for information without overloading the label design. But what precise machine technology is behind the production of these space-saving wonders? The Gallus Labelmaster demonstrates the interplay of efficiency, precision and flexibility in multi-web label production.

Images: Gallus

Multilayer labels are firmly established in all market segments. In the pharmaceutical sector, they can be found on folding cartons, vials, cans and blister wallets, where they are used as multi-layer labels to clearly communicate dosage instructions, warnings and information on ingredients. In the food sector, they enable the explicit labelling of extensive ingredients and additives, origin information and allergens. For multilingual versions in particular, multi-layer labels offer the necessary space to compactly display information in all language variants. On packaging for the household segment, they convey important warnings or handling instructions. Not forgetting the security sector, where they are used as void labels. An attempt to peel off these labels irreversibly separates the film and adhesive and reveals a void lettering or pattern - as clear proof of tampering. In logistics and e-commerce, they are used for product tracking or returns control and hardly a day goes by without new applications being added.

Production process with sophisticated web guidance

The easiest way to explain the differences in the production process for multi-layer labels is to look at them from the substrate side. A common production method is based on a single substrate web. First the back and then the front of the substrate are printed and the web is separated into panels. The individual webs are then stacked on top of each other to form a multi-layer label. The result in this example is a three-layer label with five printed sides. The maximum label width is limited to around a third of the original web width. The manufacturing process is different for a machine with several unwinders, where the production is carried out from several substrate webs. This production method enables the use of different substrates and the production of large quantities. Printing machines with a modular design are equipped with up to three unwinders and often with 12 or more printing units in a row. Additional applications such as cold or hot foil applications can also be included on a rail above the printing units, so that further options for unwinding and rewinding can be utilised there. Precise web transport plays a decisive role in the multi-web application. Only with the highest accuracy can different substrates such as polypropylene, polyethylene and paper webs be precisely merged into a label. This is ensured by a very precise machine control system, which adjusts the unwinding and web feed of the materials according to their respective modulus of elasticity - a decisive factor, as the elongation properties of these materials differ greatly.

With register control in the longitudinal and transverse directions, one web is defined as the master, while the other webs are synchronised with it. Controlled in this way, the material webs are perfectly synchronised for precise and stable further processing. If existing machine systems from the Gallus Labelmaster series are to be expanded to include multi-web labels, the "System to Compose" with its modular structure offers the necessary options. Flexo and screen printing units can be added to any machine system, for example for reverse side printing as the first work step, as well as for haptic effects or the application of Braille fonts. The addition of a digital printing unit enables one to four-colour printing of variable data, with optional colour space expansion to include orange and violet.

From the roll to the multi-layer label

The production of multi-layer labels differs from classic self-adhesive labels (PSL) right from the roll material processing stage. The printing sequence often begins with printing the reverse side. To do this, the web is unwound with the liner facing upwards, the substrate and liner are separated and the open adhesive backing is printed in the first flexographic printing unit, as shown here with the "Body Sport" sample label. The two layers are then brought back together, pressed and the web is turned for front printing. The four-colour design is then printed in four flexographic printing units (CMYK). The next finishing step is a cold foil transfer and - most importantly - the neutralisation of the adhesive on the reverse side. Various processes are available for this, such as release varnish or glue killer. In this case, a release varnish is applied to the front so that the individual sides of the multi-layer label can be opened easily. In the next step, haptic effects are applied in a screen printing unit before the webs are cut and precisely superimposed to form the multi-layer label.

The example label illustrates the high demands that the production of multi-layer labels places on the machine configuration. Fast and flexible changeover of the machine system is a decisive factor for efficient production. As the designs of multi-layer labels require very different processing sequences, it must be possible to place flexographic and screen printing units and die-cutters in different positions in the machine depending on the job. Where one job just required a screen printing unit in the machine sequence, the next job requires a die-cutter in the same position. Efficiency in production is therefore achieved by the fact that the modules can be exchanged easily, quickly and flexibly.

Machine concept important for a stable production process

Other features that are crucial for the efficient production of multi-layer labels include the ease of operation and control of the machine via the HMI. On longer machines in particular, the system supports the operator by displaying the status of the printing units, the register accuracy and the processes on the rail above the printing units at all times. This includes parameters such as tension or the status of web tension units and web edge regulators - regardless of the operator's location at the machine. Especially in the production of multi-layer labels with long web paths, the amount of waste plays a key role in effective and sustainable production. With the Gallus Labelmaster, this aspect is optimised with a short web path of just 1.4 m between the printing units and a compact arrangement of all key processes on the primary level. This eliminates additional web paths of 4 to 6 metres that would arise when changing to other machine levels. This reduces waste, saves time and cuts costs, especially with frequent job changes. At the same time, short web paths lead to a high level of stability in the production process, which optimises the use of materials in multi-layer labelling and ensures simple operation and high efficiency. (hw)