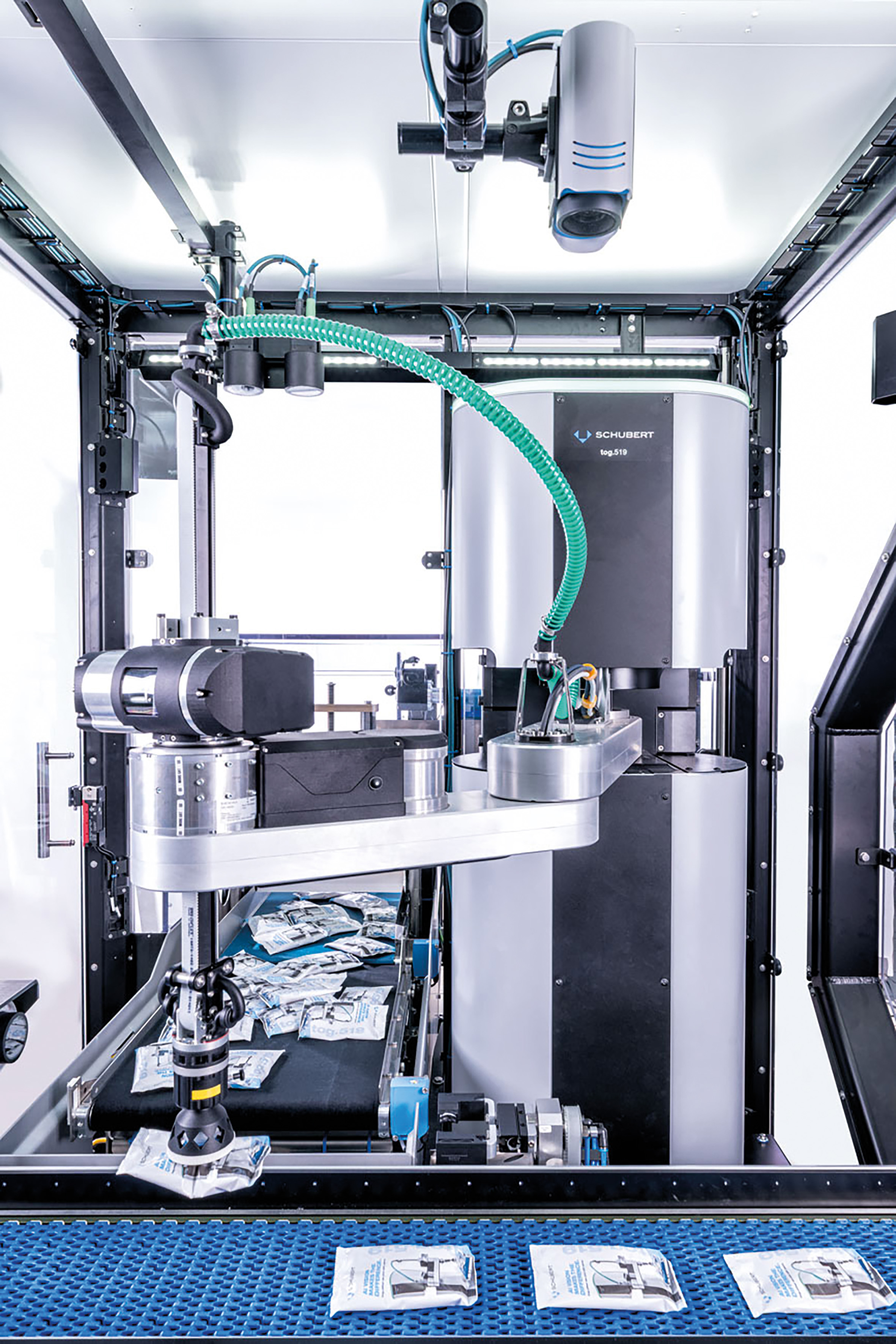

Cobot tog.519

Pick like a pro

The Cobot tog.519 from Schubert combines intuitive operation with flexibility in handling different consumer goods. The cobot reaches into the mess at up to 90 cycles - the optimum speed for efficient pick-and-place, according to the company. The simple operation enables quick adaptation to seasonal products or production peaks. Thanks to its Scara kinematics, the Cobot works up to 20 per cent faster, more energy-efficiently and with less mechanical stress than conventional solutions on the market, according to Schubert.

Cobot tog.519

Pick like a pro

The Cobot tog.519 from Schubert combines intuitive operation with flexibility in handling different consumer goods. The cobot reaches into the mess at up to 90 cycles - the optimum speed for efficient pick-and-place, according to the company. The simple operation enables quick adaptation to seasonal products or production peaks. Thanks to its Scara kinematics, the Cobot works up to 20 per cent faster, more energy-efficiently and with less mechanical stress than conventional solutions on the market, according to Schubert.

No expensive 3D camera is required for product recognition. A 2D camera is sufficient to capture disorganised products and their surroundings for precise placement. The camera uses AI-supported image recognition to identify different formats without complex programming. The tog.519 also recognises and picks completely new products immediately.

The range of applications for the tog.519 includes picking up and placing a wide variety of products to fill boxes and trays or to load chains and belts that serve cartoning, flow-wrapping, wrapping and other machines.

Cobots before and after a filling station, for example, place packaging materials such as bottles, pumps or jars and close the filled containers with lids. The tog.519 can be easily combined with machines from different manufacturers.

The AI technology enables the cobot to immediately process products of the same category with variable sizes, materials or thicknesses. Users can also train the tog.519 on new product groups using their own image material. 3D-printed tools are designed to ensure gentle product handling.